Model InSystem 003

v-heavy

up to 20

objects

per second

objects / sec

up to 36

tons

per hour

Optical separator is a high-tech equipment designed for automatic sorting and separation of various materials using advanced optical technology. This machine allows for high precision recognition of materials by colour, size, shape and chemical composition, which makes it indispensable in recycling and disposal processes, as well as in production.

PURITY LEVELS

Ai + NiR camera

input size up to 250 mm

195 000 €

Model InSystem 003

v-heavy

up to 20

object

per second

up to 36

tons

per hour

Optical separator is a high-tech equipment designed for automatic sorting and separation of various materials using advanced optical technology. This machine allows for high precision recognition of materials by colour, size, shape and chemical composition, which makes it indispensable in recycling and disposal processes, as well as in production.

PURITY LEVELS

ai + nir

camera

input size up

to 250 мм

From 85 000 €

Model InSystem 003

V-heavy

up to 20

objects

per second

up to 36

tons

per hour

Optical separator is a high-tech equipment designed for automatic sorting and separation of various materials using advanced optical technology. This machine allows for high precision recognition of materials by colour, size, shape and chemical composition, which makes it indispensable in recycling and disposal processes, as well as in production.

PURITY LEVELS

Ai + NiR camera

input size up to 250 мм

195 000 €

Detaled review

Our team will be happy to help you with your specific questions and requests.

Irina Tserush

Manager

Contact us >

Sorted materials

_edited.png)

* A few words about the sorted materials: stone, potatoes, wood.

* The paragraph is devoted to the advantages of sorting with this equipment.

STONE

WOOD

POTATOES

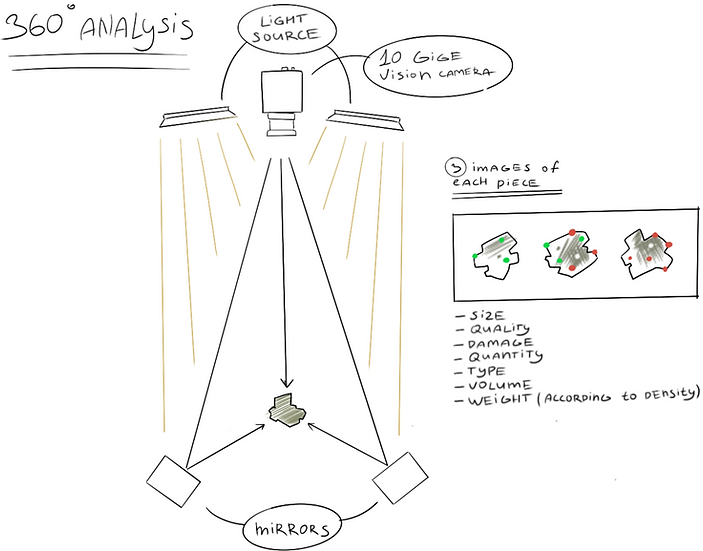

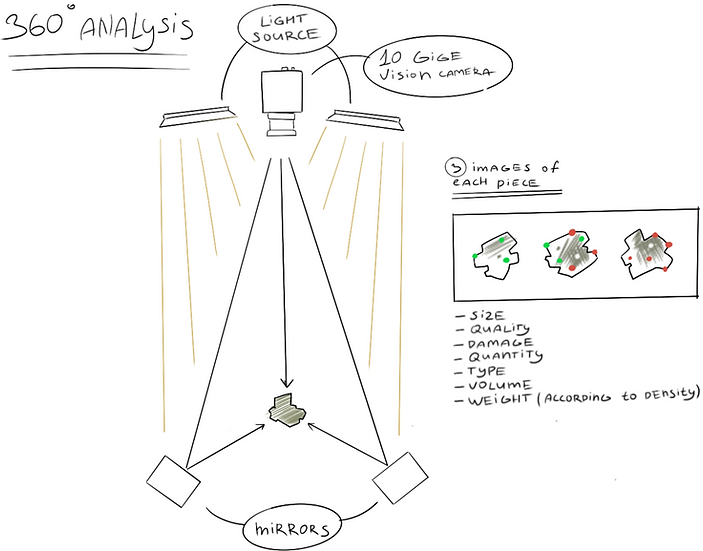

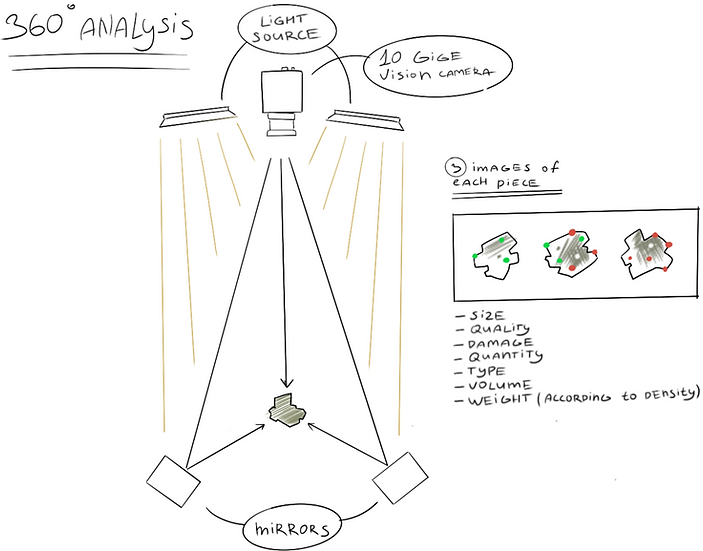

360° camera

The high-speed camera with dual mirror system provides a 360-degree comprehensive view of the object, allowing the smallest details to be captured at high speed. Thanks to its unique optical design, the camera can capture images from all sides simultaneously, making it indispensable in industrial applications where precise quality control and analysis of fast-moving processes is required. The high resolution and speed of capture ensure that even the most complex objects are examined in detail, providing reliable data for optimising production.

360° camera

The high-speed camera with dual mirror system provides a 360-degree comprehensive view of the object, allowing the smallest details to be captured at high speed. Thanks to its unique optical design, the camera can capture images from all sides simultaneously, making it indispensable in industrial applications where precise quality control and analysis of fast-moving processes is required. The high resolution and speed of capture ensure that even the most complex objects are examined in detail, providing reliable data for optimising production.

360° camera

The high-speed camera with dual mirror system provides a 360-degree comprehensive view of the object, allowing the smallest details to be captured at high speed. Thanks to its unique optical design, the camera can capture images from all sides simultaneously, making it indispensable in industrial applications where precise quality control and analysis of fast-moving processes is required. The high resolution and speed of capture ensure that even the most complex objects are examined in detail, providing reliable data for optimising production.

Statistics

.jpg)

The high-speed camera and Ai provides up to 100 frames per secondobject analisys. The high resolution and speed of capture ensure that even the most complex objects are examined in detail, providing reliable data for optimising production.

REALTIME

STATISTICS

REMOTE CONNECTION

HIGH-SPEED

AI UPDATE

CLOUD MONITORING

.jpg)

Statistics

The high-speed camera and Ai provides up to 100 frames per secondobject analisys. The high resolution and speed of capture ensure that even the most complex objects are examined in detail, providing reliable data for optimising production.

REALTIME

STATISTICS

REMOTE CONNECTION

HIGH-SPEED

AI UPDATE

CLOUD MONITORING

_edited.png)

Sorted materials

* A few words about the sorted materials: stone, potatoes, wood.

* The paragraph is devoted to the advantages of sorting with this equipment.

STONE

WOOD

POTATOES

Statistics

The high-speed camera and Ai provides up to 100 frames per secondobject analisys. The high resolution and speed of capture ensure that even the most complex objects are examined in detail, providing reliable data for optimising production.

REALTIME

STATISTICS

REMOTE CONNECTION

HIGH-SPEED

AI UPDATE

CLOUD MONITORING

Sorted materials

* A few words about the sorted materials: stone, potatoes, wood.

* The paragraph is devoted to the advantages of sorting with this equipment.

STONE

WOOD

POTATOES

Design and construction

This modular design allows for easy integration into existing production lines and can be configured in a series, with each unit sorting specific fractions and passing remaining materials to the next separator. The robust frame and adaptable support structure ensure stability and flexibility in various industrial settings.

constituent

material

Frame

Steel

Support structure

Steel, stone

Conveyor belt

High-strength

rubber

Design and construction

The V-belt high speed conveyor is designed to maximise efficiency in production processes. The unique design allows the conveyors to be installed in a chain, where each sifts its own fraction and passes the remaining material to the next. The interchangeable footplate, adaptable for mounting on a lego block or on a frame, provides flexibility of installation and easy integration into different production lines. This modular system guarantees precise sorting and optimised space utilisation, increasing overall productivity.

constituent

material

Frame

Steel

Support structure

Steel, stone

Conveyor belt

High-strength rubber

Design and construction

The V-belt high speed conveyor is designed to maximise efficiency in production processes. The unique design allows the conveyors to be installed in a chain, where each sifts its own fraction and passes the remaining material to the next. The interchangeable footplate, adaptable for mounting on a lego block or on a frame, provides flexibility of installation and easy integration into different production lines. This modular system guarantees precise sorting and optimised space utilisation, increasing overall productivity.

CONSTITUENT

MATERIAL

Frame

Steel

Support structure

Steel, stone

Conveyor belt

High-strength rubber

Technical details

and specifications

The Optical Sorter - Line features an advanced self-calibration system for optimal performance under varying conditions. Its proprietary software enables remote monitoring and real-time adjustments, while the modular design allows for easy customization to meet specific industry requirements without complete system replacement.

BASIC PARAMETRES

Capacity

12 000kg/h

Power consumption 5 kVt

FRACTIONS

Up to 6

separate fractions

Input fraction size <150 mm

CONVEYOR

High-frequency technology

Conveyor speed

3-4 m/s

AUTOMATIC OIL SYSTEM

Highly precise

360 analysis

Technical details

and specifications

The high-speed conveyor with V-belt is made of wear-resistant materials resistant to mechanical damage and chemical influences. It is equipped with a powerful variable speed drive system and a state-of-the-art control system with touchscreen interface, allowing it to be precisely customised for different applications. The modular design ensures easy transport, installation and maintenance, as well as the ability to quickly expand production capacity.

BASIC PARAMETRES

Capacity 12 000kg/hour

Power consumption 5 kVt

FRACTIONS

Up to 6 separate fractions

Input fraction size <150 mm

CONVEYOR

High-frequency technology

Conveyor speed 3-4 m/s

Camera

Highly precise 360 analysis

Parameters

Significance

Overall dimensions

4900х2150х1400 mm

Minimum and maximum size of sorted objects

0-300 mm

Power consumption

5 kVt per hour

Operating temperature range

from -20 to +40 °C

Weight

1150 kg

Technical details

and specifications

The Optical Sorter - Line features an advanced self-calibration system for optimal performance under varying conditions. Its proprietary software enables remote monitoring and real-time adjustments, while the modular design allows for easy customization to meet specific industry requirements without complete system replacement.

BASIC PARAMETRES

Capacity

12 000 kg/h

Power consumption

5 kW

FRACTIONS

Up to 6

separate fractions

Input fraction size <150 mm

CONVEYOR

High-frequency technology

Conveyor speed

3-4 m/s

CAMERA

Highly precise

360 analysis

Parameters

Significance

Overall dimensions

4900х2150х1400 mm

Minimum and maximum size

of sorted objects

0-300 mm

Power consumption

5 kW/h

Operating temperature range

from -20 to +40 °C

Weight

1150 kg

Parameters

Significance

Overall dimensions

4900х2150х

1400 mm

Minimum and maximum size

of sorted objects

0-300 mm

Power consumption

5 kVt per hour

Operating temperature range

from -20

to +40 °C

Weight

1150 kg

Compressed

air requirements

8 bar,

2000 L/min